Miles of Fiber, Tons of Insight: Halff’s Role in Designing FDOT’s Weigh-in-Motion Network

Can you imagine what it takes to connect driver data across an entire state?

More than 20 million trucks are weighed every year in the state of Florida, which contains an impressive fiber optic network spanning 2,000+ miles. Behind this cutting-edge network design is the work of Halff’s ITS team to develop more efficient (and scalable) weigh station infrastructure and truck ramps.

Background

As the subconsultant to WGI, Inc., Halff supported the development of a Weigh-In-Motion (WIM) screening system in Flagler County, FDOT District 5.

Halff is operating under a continuing services contract for FDOT’s Central Office Motor Carrier Size and Weight (MCSAW) division, designing and developing various projects; notably the WIM design.

The “Weight” Is Over

Static truck scales are not only costly to maintain, but a massive slow down for truckers.

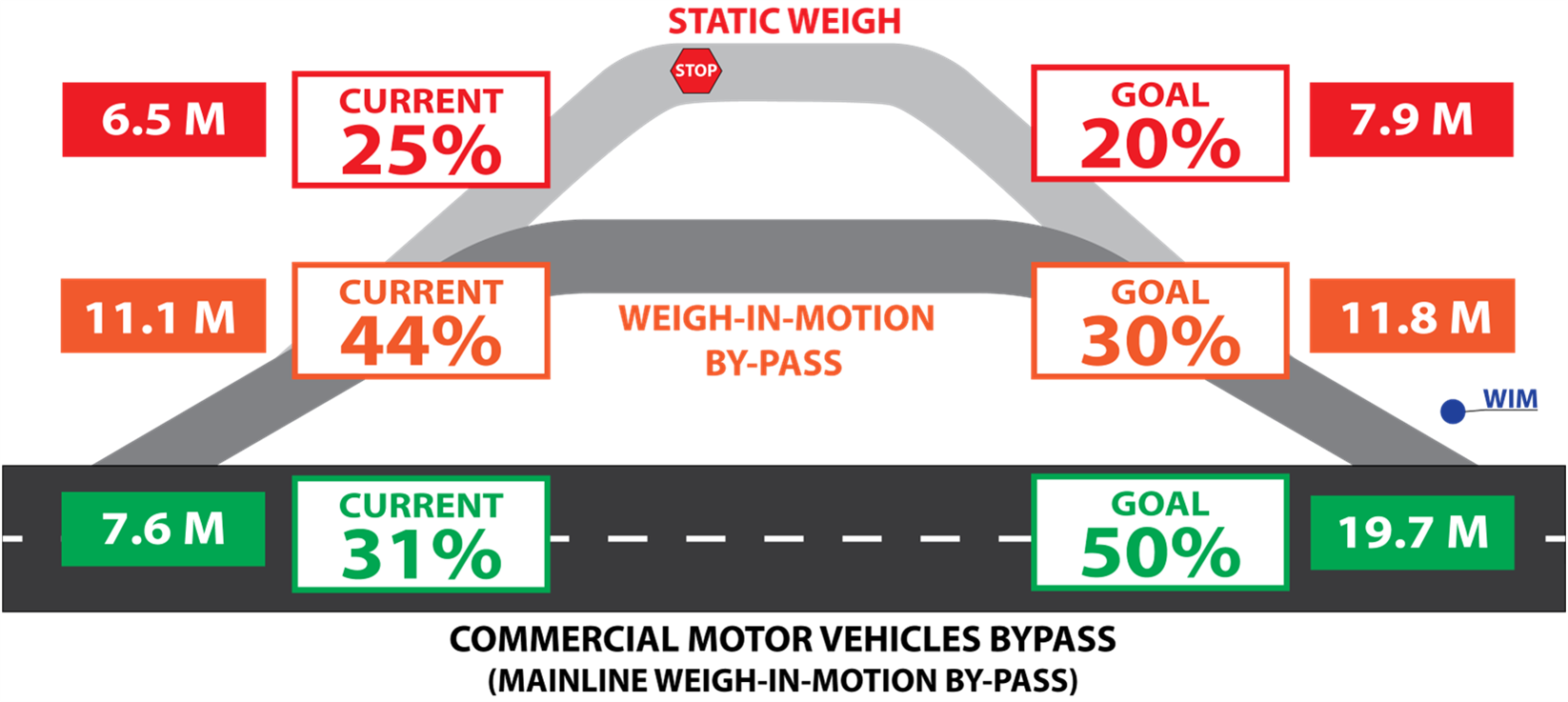

The purpose of the mainline WIM system was to minimize the number of trucks being pulled in for static weighing and inspection into the weigh station. The initial goal was to achieve a 60% reduction of trucks being pulled in. Results surpassed this goal, as the new WIM system achieved an 80% reduction within the first few months of the first location being opened.

Reducing wear and tear on the static scales is not the only advantage. Permit issued loads will be more easily detected by scanning the truck’s DOT number. Plus, the new system on the main line requires less maintenance compared to static scales, saving both time and money for truck drivers and FDOT.

Additionally, reducing the number of trucks entering the weigh stations will minimize the need for trucks to merge back into mainline traffic at mainline speeds after a static weight and inspection. This brings a safer way for trucks to be weighed and inspected without weaving into high-speed traffic.

These weigh-in-motion stations also use advanced technology to capture tire anomalies—such as low pressure and low tread, which poses dangers for truck drivers and surrounding traffic—and can detect oversized or overweight truck loads.

All this valuable data ultimately can help generate revenue for the state of Florida to then reinvest into Florida’s roadway and the motor carrier system.

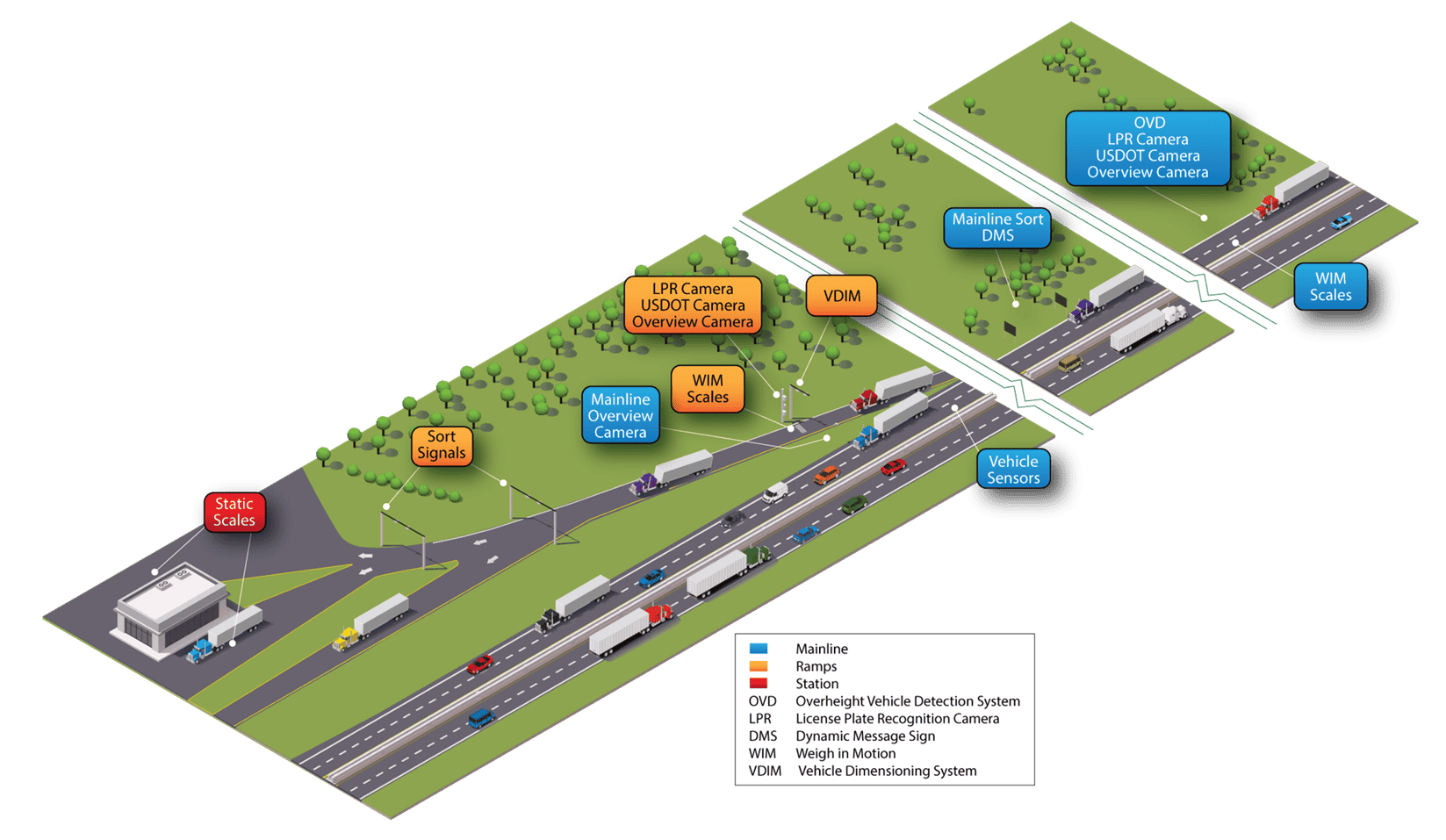

Depiction of weigh-in-motion stations that provide seamless, efficient access for trucks along interstates.

Building Synergy Across Florida

A project in conjunction with these newly-advanced weigh-in-motion stations is the establishment of a redundant statewide network.

Leaps and bounds of progress are being made while the statewide network is still under construction. The statewide network, designed by Halff and FDOT, connects motor carrier weigh stations with fiber optic communication and wireless networks—bundled together into one tracking system.

This state-of-the-art system spanning 2,000+ miles across Florida provides ways for these weigh stations to communicate with each other, syndicating data cohesively. It can recognize when and where a truck has driven and what its weights were at those given time stamps.

It ultimately saves commercial truckers and FDOT time and money by efficiently screening vehicles required to enter the static weigh stations.

The result improves communication and efficiency and shows newfound insights into travel patterns and other key data that will shape the future of efficient traffic operations in Florida.

Halff’s Role in the Road to Success

Halff designers and engineers have performed or assisted with all nine of the WIM systems designed or constructed at the weigh stations.

Halff’s own Bryan Hubbard conceived the idea for the project during his tenure at FDOT, adding a deeper layer of understanding and expertise.

“During the project, new signage had to be updated so drivers could better see it,” said Halff’s Matthew Thibault. “From an end user standpoint, there were multiple iterations that had to take place to properly clarify and improve the system.”

The project involved iterative updates to signage and system timings. Halff’s ITS team helped implement new signage to further improve driver comprehension and system efficiency, based on driver feedback and observed issues.

Drivers will benefit from the efficiencies created while minimizing the amount of over-hour service (10 hours of drive time per day).

Driving Innovation Forward

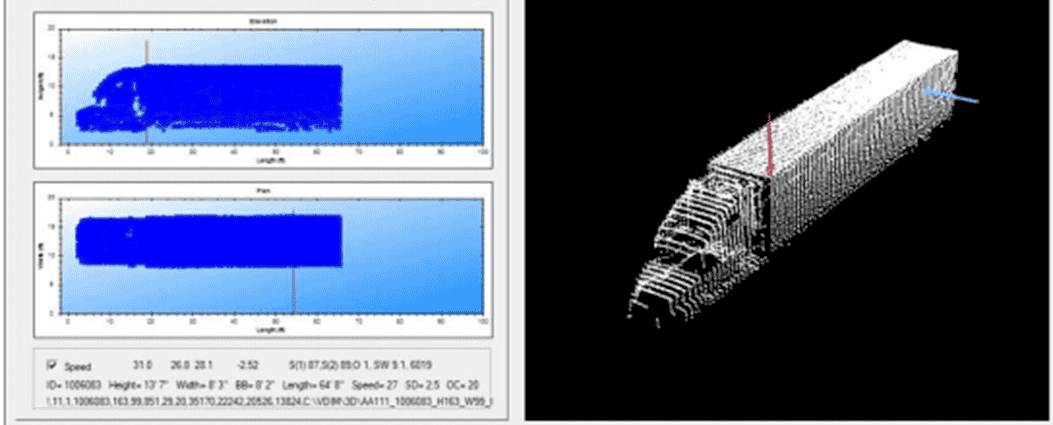

Truck lidar diagrams showing multiple angles and viewpoints.

The foundation of valuable data provided by these WIM stations will be an integral piece for the future of traffic operations and capacity projects.

More technology can eventually be added, like hazard placard readers and thermal technology, as these systems were designed to be scalable and grow with the needs of the MCSAW division and the department. It also enables growth and system expansion to MCSAW’s virtual sites.

The innovation doesn’t stop there. Connecting each WIM station together with fiber optic networks, Artificial Intelligence (AI) will eventually be able to detect patterns and driver routines.

All this data provides potential for the planning industry. As the system identifies the origins and destinations of trucks’ traffic patterns, data can be analyzed by traffic operations groups to understand these patterns and which corridors are commonly utilized. This feedback will help determine what projects need to be prioritized, such as resurfacing, pavement rehabilitations and more.

Florida’s ITS network is shifting into high gear, connecting more efficient WIM stations with smarter and faster insights.

And when it comes to innovation for the future, Florida’s infrastructure is certainly on the right track.

Halff’s trusted ITS team is here to help. Our multi-discipline teams know how to meet the challenges of evolving technology and help our clients incorporate Intelligent Transportation Systems (ITS) into today’s roadways.

Let Halff help you take the first step by contacting Senior Team Leader of Transportation Matthew Thibault (mthibault@halff.com).